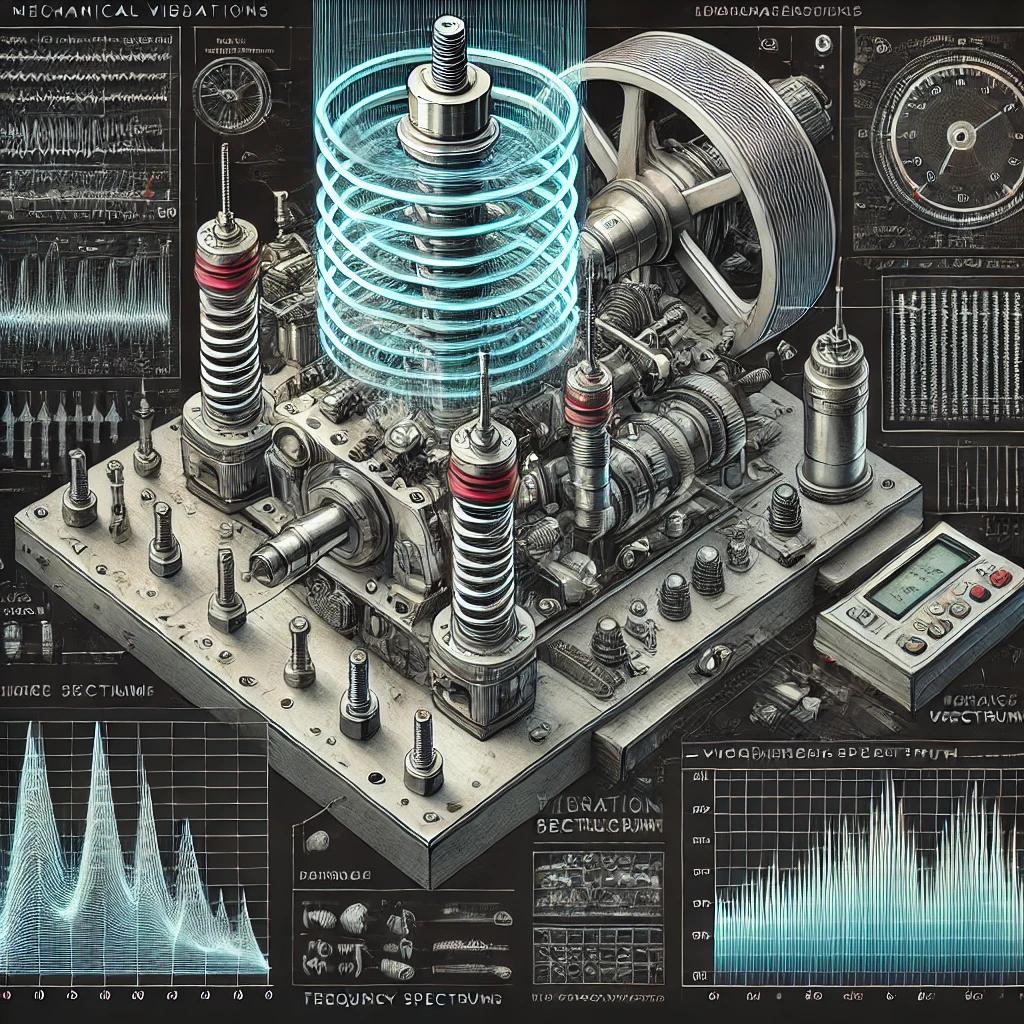

Mechanical Vibrations: What Are They, Why Do They Occur, and How Are They Controlled?

Introduction

Mechanical vibrations are critically important in the engineering world for understanding the dynamic behavior of machines and structural systems. Vibrations can be defined as the periodic deviation of a system from its equilibrium position. This phenomenon can lead to unwanted noise and wear, but it can also be beneficial in certain applications. In engineering, accurate analysis and control of vibrations are essential for the reliability and performance of systems.

Types of Vibrations

Vibrations can be classified based on their characteristics:

-

Free Vibrations: These occur at the system's natural frequency without any external force acting on it. For example, the oscillation of a mass on a spring.

-

Forced Vibrations: These occur due to an externally applied periodic force. For instance, vibrations caused by an operating engine.

-

Damped and Undamped Vibrations: Damping refers to the resistance forces that cause vibrations to decrease over time. In undamped vibrations, no energy loss occurs, whereas in damped vibrations, the amplitude decreases due to energy loss.

Causes of Vibrations

The primary causes of vibrations in mechanical systems include:

- Imbalances: A misalignment between the center of mass and the axis of rotation in rotating parts can cause vibrations.

- Misalignment: Incorrect alignment of shafts or components can increase vibrations.

- Loose Parts: Assembly errors or loose connections can trigger vibrations.

- External Forces: External factors such as wind, earthquakes, or other forces acting on a machine can induce vibrations.

Vibration Analysis

The primary methods used in vibration analysis include:

- Frequency Analysis: Decomposing the vibration signal into its frequency components helps determine the dominant frequencies of vibration.

- Mode Shapes: These illustrate how a system vibrates at its natural frequencies and are crucial in structural analysis.

- Spectrum Analysis: Examining the frequency spectrum of a vibration signal can help detect potential faults in a system.

Vibration Measurement Devices

Various sensors are used for accurate vibration measurement:

- Accelerometers: Measure vibration acceleration and provide precise measurements across a wide frequency range.

- Velocity Sensors: Measure vibration velocity and are typically used for medium-frequency vibrations.

- Displacement Sensors: Measure the amplitude (displacement) of vibrations and are preferred for low-frequency vibrations.

Effects of Vibrations

Vibrations can have several impacts on mechanical systems:

- Machine Performance: Excessive vibrations can negatively affect machine performance and reduce efficiency.

- Structural Damage: Continuous vibrations can lead to fatigue and cracks in structural components.

- Noise Levels: Vibrations can generate unwanted noise, affecting the work environment.

Vibration Control Methods

To minimize and control vibrations in mechanical systems, the following methods are used:

1. Passive Control

This method involves using mechanical components or materials to reduce vibrations.

- Vibration Dampers: Rubber, elastomer, or viscoelastic materials absorb vibrations.

- Mass-Damper Systems: Springs and damper mechanisms are added to alter or reduce vibration propagation.

- Vibration Isolation: Special isolation materials are used to prevent vibrations from spreading to the ground or surrounding structures.

2. Active Control

These systems dynamically detect vibrations and apply counteracting forces to balance them.

- Active Damping Systems: Sensors and actuators apply real-time vibration-reducing forces.

- Anti-Vibration Mechanisms: Counterweights or dynamic balancing systems are used in rotating systems to control vibrations.

Vibration Damping Materials

Various materials are used to reduce vibrations:

- Elastomers: Rubber-based materials absorb vibrations due to their flexibility.

- Viscoelastic Materials: These materials, which have both elastic and viscous properties, maximize energy absorption.

- Metallic Dampers: Preferred in systems operating under high temperatures and heavy loads.

Industrial Applications of Vibrations

Mechanical vibrations play a crucial role in many industries:

- Automotive Industry: Vibration control is essential in vehicle engines, suspension systems, and braking systems.

- Aerospace and Aviation: Minimizing vibrations in aircraft engines and structures enhances safety.

- Civil Engineering: Buildings use vibration dampers to mitigate earthquake effects.

Effects of Vibrations on Human Health

Prolonged exposure to vibrations can cause various health issues:

- Vibration-Induced Disorders: Long-term exposure can lead to joint problems and circulatory disorders.

- Ergonomic Considerations: Reducing vibration levels in the workplace helps protect workers' health.

- Protective Measures: Anti-vibration gloves and insulated workspaces can help prevent health issues.

Software in Vibration Analysis

Various software tools are used for vibration analysis and simulation:

- Finite Element Analysis (FEA): Used for structural vibration analysis.

- Modal Analysis Software: Determines the natural frequencies of machine components.

- Data Collection and Processing Programs: Used for real-time vibration measurements.

Vibration Testing and Standards

International standards define procedures for measuring and evaluating vibrations:

- ISO Standards: Establish international rules for machine and structural vibrations.

- ASTM Test Methods: Assess the vibration damping properties of materials.

- Calibration Procedures: Ensure the accuracy of vibration measurement devices.

Vibration Monitoring and Maintenance

Regular monitoring and maintenance of vibrations extend machine lifespan and prevent failures:

- Condition Monitoring: Real-time vibration data is monitored using sensors and data analysis software.

- Preventive Maintenance: Potential failures are detected in advance to optimize maintenance processes.

- Fault Diagnosis: Vibration data is analyzed to identify possible issues in machines.

Vibration Training and Certification

Engineers and technicians seeking expertise in mechanical vibrations can access various training programs:

- Engineering Education Programs: Included in mechanical engineering courses at universities.

- Professional Certifications: Can be obtained through training aligned with ISO and ASTM standards.

- Continuous Training and Development: Workshops and seminars help professionals stay updated with new technologies.

Future Vibration Technologies

With technological advancements, vibration analysis and control methods continue to evolve:

- Smart Sensors: Advanced vibration measurement devices that collect and analyze real-time data.

- IoT and Vibration Monitoring: Remote monitoring and control systems enabled by internet-connected devices.

- Artificial Intelligence in Analysis: Machine learning algorithms improve the accuracy of vibration data interpretation.

Conclusion

Mechanical vibrations play a significant role in engineering, and improper analysis can lead to serious problems. By using vibration measurement devices, analysis techniques, and control methods, machines can operate safely, efficiently, and with greater longevity. In the future, AI-supported systems and smart sensors will enhance vibration analysis, making maintenance processes more efficient.