Assembly

When lifting and moving the booster device, we lift it safely with the help of a sling and protect it against external weather conditions and freezing. There should be no obstruction to the normal air flow for cooling through the fan cover holes of the motors. The booster should be placed on a flat concrete or equivalent surface using the 4 rubber wedges provided. Larger industrial type hydrophores are fixed to the ground with appropriate bolts and dowels.

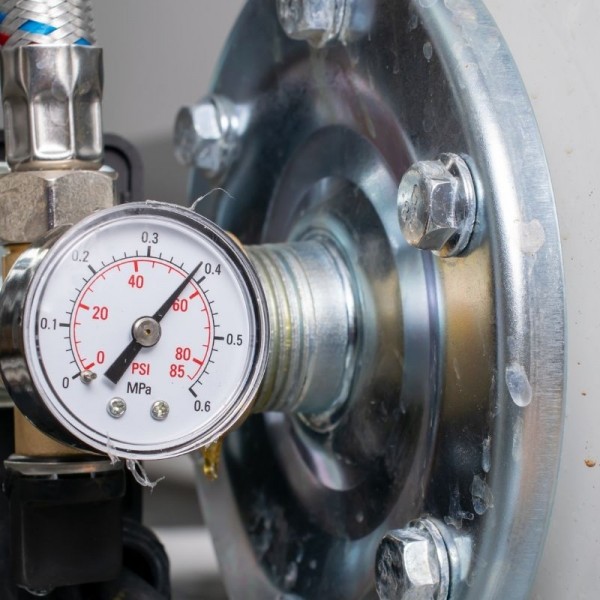

Suction and Discharge Pipes

Pipes resistant to maximum booster pressure should be used, the suction pipe should be well sealed and the suction pipe should be of appropriate size. The suction pipe diameter must be at least the booster collector or pump inlet diameter or larger. The suction pipe of a hydrophore that will operate by suction from an underground water tank or source should be as short as possible, have a single elbow and at least the pump inlet diameter, and should be made with a slope of 1-2% rising from the elbow towards the pump. In reverse inclined installations, it creates an air pocket and the pump cannot suction. It is undesirable to use a non-return valve at the pump outlet other than a vertical valve or non-return valve attached to the end of the pipe. When the check valve or vertical flap is broken, the hydrophore will leak water, causing pressure loss, and frequent activation of the hydrophore will make itself felt and ensure maintenance. Otherwise, the malfunction of the suction flap will not be felt due to the check valve in the pressure line, and since the water escaping back will not be noticed, the suction line will remain dehydrated, causing damage to the pump or pumps. Another issue is that it is extremely undesirable to use a common suction collector in multi-pump booster systems. Due to the large diameter of the suction collector, the suction flap will also be large, causing a separate load loss if a single pump operates, and most importantly, if it breaks down, it will cause damage to all pumps in the booster set. Therefore, in multi-pump systems, it is of great benefit to have the pumps primed separately.

What are the usage areas of hydrophore?

- Supplying pressurized water needed in residences, apartments, commercial buildings (offices, dormitories, hotels, hospitals, etc.).

- In garden irrigation systems with automatic water distribution (sprinkler) system.

- In water purification (RO-Reverse osmosis) systems.

- In systems requiring pressurized water in industrial processes.

- Within the scope of fire fighting, in the supply of necessary pressurized water in wet extinguishing systems (sprinklers).

As Geta Engineering, we install booster systems with care and provide the best solutions to our customers with promptness and professionalism.